At the beginning of 2018, a dream has been touching his heart. A helicopter and a brand were born because of him. He is Li Junjie, a member of the F3C China national team and a leader in the design of China's F3C remote control helicopter.

Accumulated 18 years of experience in remote-controlled helicopter flight and competition told him that the design of F3C helicopter should usher in changes of the times.

As we all know, the full weight of the aircraft will directly affect the flight performance and the accuracy of stunts. The concept of lightweight flight has been throughout Li Junjie's flight career. It took him only a short year from refitting to the birth of his own brand [rve].

The full weight of F3C competition class helicopter has been reduced from 6200g to 5200g of Merak (including the take-off weight of full body and battery), and the weight has been reduced by 16%.

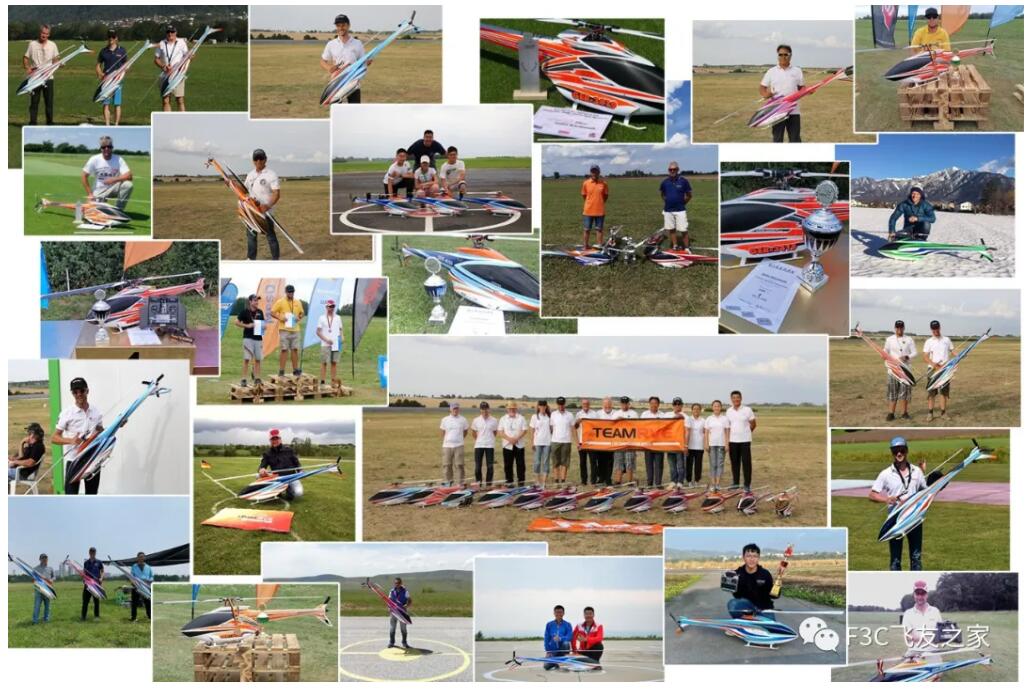

As soon as the first generation of Merak E750 helicopter came out, it caused great repercussions in the industry. F3C professionals and remote-controlled helicopter enthusiasts all over the world began to order and experience flight. Since then, the precise and lightweight design of Merak E750 has changed the world of remote-controlled helicopter.

In the following two years of f3cn telecontrol helicopter world championship, national aerospace model Championship (F3C, f3c-p project), National Youth aerospace model Championship (F3C, p3c-2 project) and other projects, Merak E750 occupied the first place in the number of helicopters in the global F3C competition with excellent flight performance and absolute c-position advantage, and won many Championship models in one stroke. Now, more than 300 users and dozens of professional players have chosen Merak around the world, and China intelligent manufacturing has once again stepped on the world stage to lead the development of the industry.

In 2020, the novel coronavirus pneumonia epidemic swept the world, and all walks of life slowed down the pace of product research and development. But the RVE team used this year's industry downturn to concentrate on the upgrading and modification of MERAK to cater for the latest FAI F3C competition requirements.

As the chief designer of [rve], Li Junjie, after thousands of flight tests, found that it is particularly important to improve the quality of flight training to improve the functional conversion rate of helicopter and the flight efficiency of single take-off and landing. After a year of painstaking research and continuous attempts, we worked hard for every 1% efficiency increase, and finally a new generation of F3C competitive artifact with many changes was born, named Merak E750 Evo.

1、 The evolution of lightweight

There is an important parameter in the design of traditional fixed wing aircraft wing load. People with a little flight foundation also know that wing load plays a crucial role in the performance of the aircraft. In fact, the same is true for helicopters, except that the "wing load" will become the rotor load. In other words, the smaller the load per unit rotor area, the smaller the inertia of the helicopter itself, so the less energy is needed to change the motion. That is to say, the lighter the weight of the helicopter, the lower the energy consumption and the better the flight performance of the helicopter.

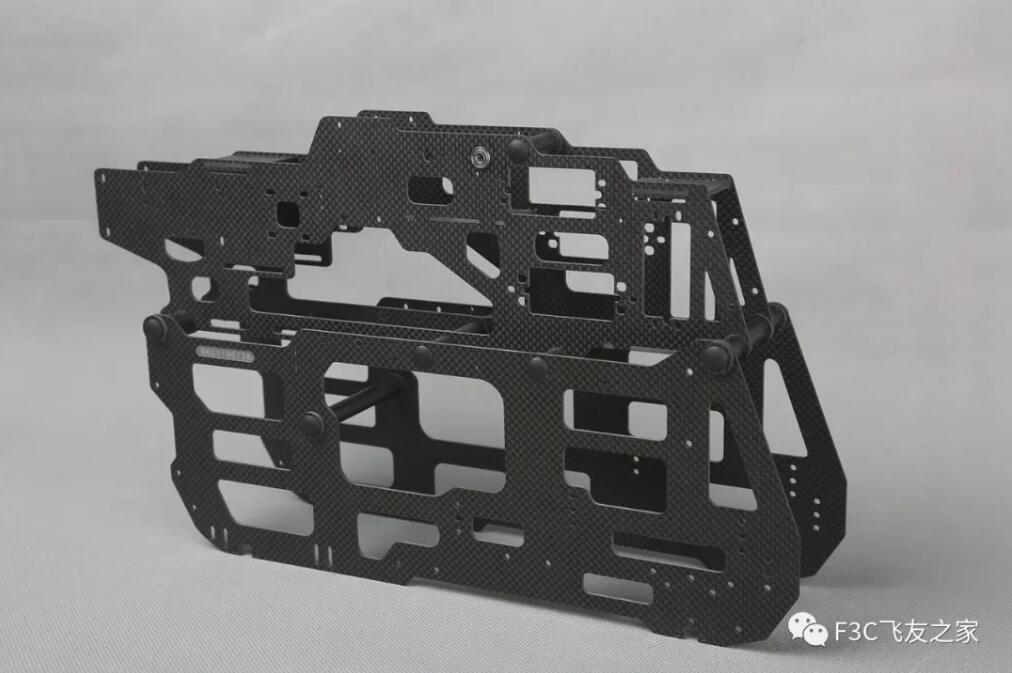

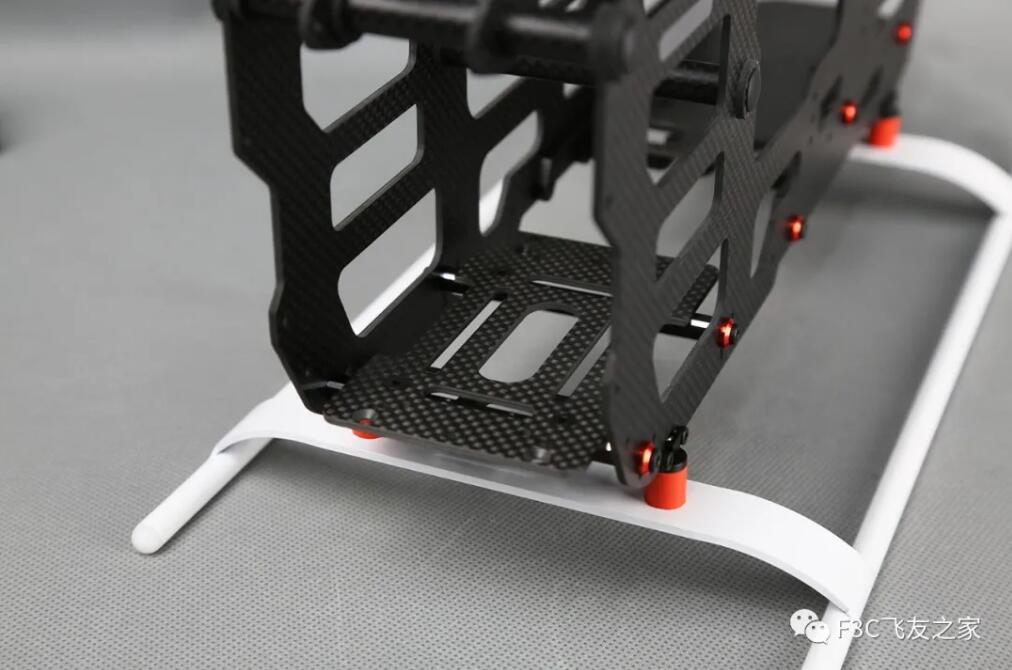

The first generation of Merak E750 was designed with weight reduction in mind. Therefore, the side plate of Merak breaks the traditional assembly process and adopts the method of hot pressing and bonding in the mold, which ensures the accuracy of fuselage assembly to the greatest extent and avoids the trouble of traditional screw installation. After many flights, the fuselage will not produce the distortion and deformation of assembly position. Don't underestimate the weight of the screws in the traditional double side panel assembly. This screw free assembly process reduces the weight of the fuselage by more than 100 grams and the total weight by nearly 2%.

Merak E750 Evo adopts the first generation fuselage design concept, and re adjusts the layout of the lightening holes, once again reducing the possibility of stress concentration in flight, and further improving the overall torsional performance.

In Evo version, the contact surface of the cross beam tube connected between the side plates of the fuselage is externally reinforced, and the box structure is used between the inner side plates to enhance the torsion resistance of the side plates.

In order to improve the stability of the tail and reduce the vibration in flight, the stern tube of Merak E750 Evo is upgraded from the first generation 22mm to the lightweight 3K thin-walled carbon fiber tube, and the stern box assembly is designed to be more lightweight, so the overall weight is not increased after upgrading.

The change of the vertical axial center of gravity position (main axis direction) of the helicopter will have an impact on the stunt performance. Merak E750 Evo has made an innovative design on the battery installation. By adjusting the battery installation mode and the position of the slide rail, the distribution of the overall center of gravity (preset with five positions) can be changed to meet the performance requirements of different pilots for the helicopter.

In order to further reduce the overall weight of the aircraft, the metal parts of Merak E750 Evo all use 7075-T651 aviation aluminum as the base material. With special structural design and processing technology, the precision and quality of the parts are improved compared with those of the first generation.

Here we summarize the advantages of lightweight design

It can use smaller capacity battery (the minimum can use 4000 MAH LiPo battery), reduce flight cost, reduce charging time and improve flight efficiency;

It can set higher flight sensitivity, improve the working efficiency of gyroscope system, and enhance the overall stability and wind resistance of the aircraft;

Faster control response speed, even with minimal rocker correction, the helicopter can respond and follow the rudder more easily;

Reduce the load of helicopter transmission components and control unit, lower failure rate and longer maintenance cycle;

To reduce the disadvantages caused by the large inertia of the helicopter, pitch control can be more delicate, vertical climbing action, somersault arc action, and action with angle can be more accurate and uniform, and dive will not be too fast, and get more beautiful graphics.

Reduce the descent rate of spin landing action, make the action more leisurely and accurate;

Reduce the energy consumption of the power system, the minimum can use 4035 power motor, 130a high-voltage electric regulator, reduce the cost of electronic equipment;

2、 Efficient change

The latest actions of FAI F3C put forward new requirements for helicopter flight performance. A large number of vertical climb, roll and roll actions require the helicopter to have efficient power system and transmission system.

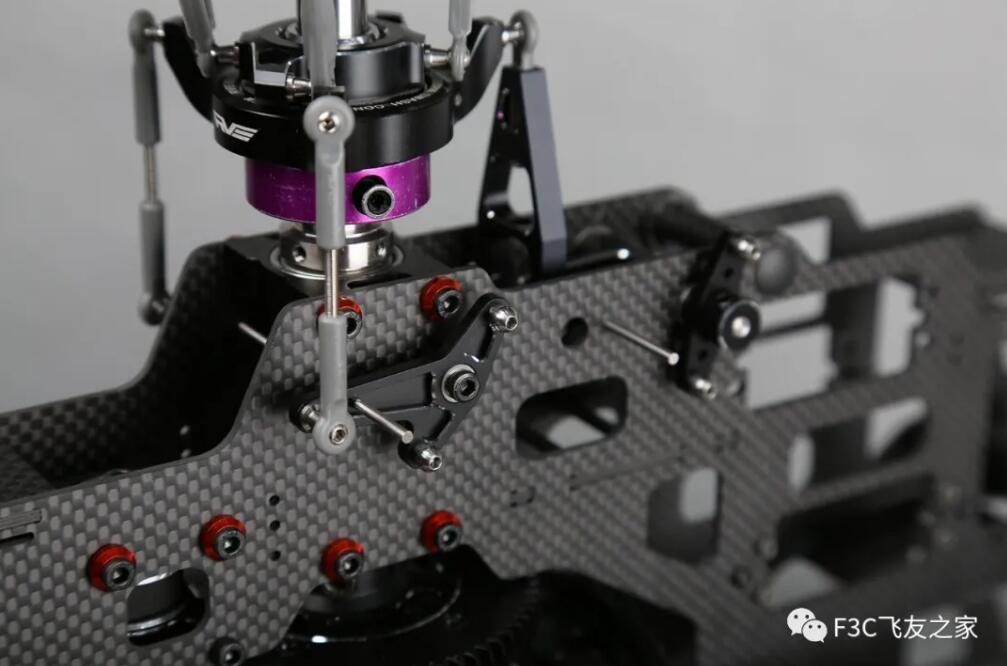

The newly designed tilting disc and rotor head, together with the new rve 765mm F3C rotor, can improve the static stability and the overall flight efficiency by 5%.

Although the design of the first generation of three tail rotor improves the performance of locking, the weight and inertia of the tail increase, which inhibits the performance of some parts. Therefore, the Merak E750 Evo is back to the dual tail propeller system, but the in-depth research on the overall structure design, through a large number of flight tests and step-by-step improvement, increases the tail locking effect of the two tail system. So the new tail rotor clamp and pitch control system came into being.

The double tail thrust structure supported by six bearings and the newly designed tail rotor clamp can greatly reduce the consumption of the tail blade actuator on the premise of ensuring the tail locking performance.

The newly designed 20t high oxidation and wear resistant coating pulley and high slope tail drive gear system greatly improve the transmission efficiency, reduce the system noise, increase the service life of parts by 100%, and avoid replacement during normal flight of 1000 takeoff and landing, so as to reduce the aircraft maintenance cost and improve the training efficiency.

The 92mm super large diameter integrated center one-way bearing seat is matched with the new generation of 20 ° helical gear plate, which greatly improves the concentricity of the whole gear set, further improves the transmission efficiency, reduces the system vibration and noise, and reduces the weight by 10% compared with the first generation.

3、 Convenient installation

The adjustable neutral point steering gear rocker arm and the tilt plate rocker arm with prefabricated adjustment holes make the adjustment of 0 pitch point more convenient, and also make your grasp of 0 pitch point more accurate in flight.

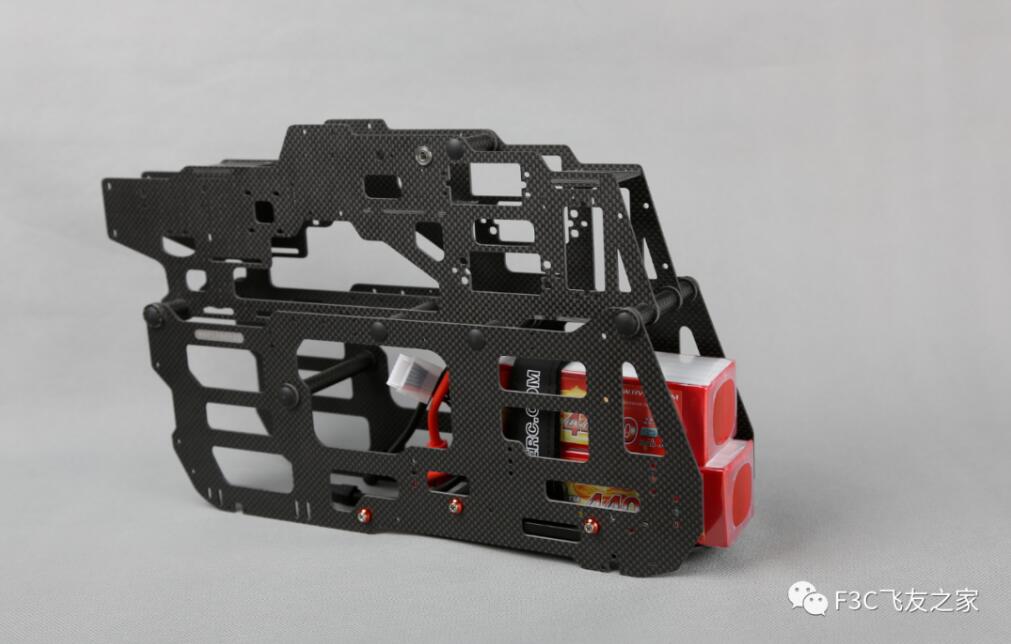

The integrated tripod mount has become the standard configuration of Merak E750 Evo, which greatly improves the strength and stability of the battery compartment. The way to change the battery in the abdomen also brings great convenience to flight.

The newly designed electric regulator mounting position can easily cope with the installation of any governor on the market that can be used for Merak E750 Evo.

Conclusion:

The new generation of Merak E750 Evo maintains the original "precision" design concept, and has carried out many innovative designs in terms of efficient and convenient flight. With the new generation of future full shell, it will help you win the championship in the competition.